Source: Xinhua Agency Views: 1.1 million

The goal is to achieve carbon peaking by 2030, and coal, which accounts for a large portion of China’s energy consumption, faces the challenge of significantly reducing carbon dioxide emissions.

"By using new coal gasification technologies that reduce pollutants and improve efficiency, carbon reduction can be achieved," said Lv Qinggang, a researcher at the Institute of Engineering Thermophysics, Chinese Academy of Sciences.

The "Circulating Fluidized Bed Coal Gasification Technology Development and Industrialization" project, led by Lv Qinggang, was recently unveiled at the 2021 China (Anhui) Science and Technology Innovation Achievement Transfer and Transformation Conference, as one of five major achievements from the Chinese Academy of Sciences.

For many, coal chemical gasification plants are associated with pungent odors, coal ash, wastewater, and waste slag. However, at the Xinjiang Yihua Coal Gasification Unit built by CAS Hefei Coal Gasification Technology Co., large gasification units are neatly arranged, and the production workshop is clean and orderly. The high-alkali coal from Xinjiang's Zhundong region, which is difficult to gasify, is converted into clean syngas.

Xinjiang Yihua Coal Gasification Project

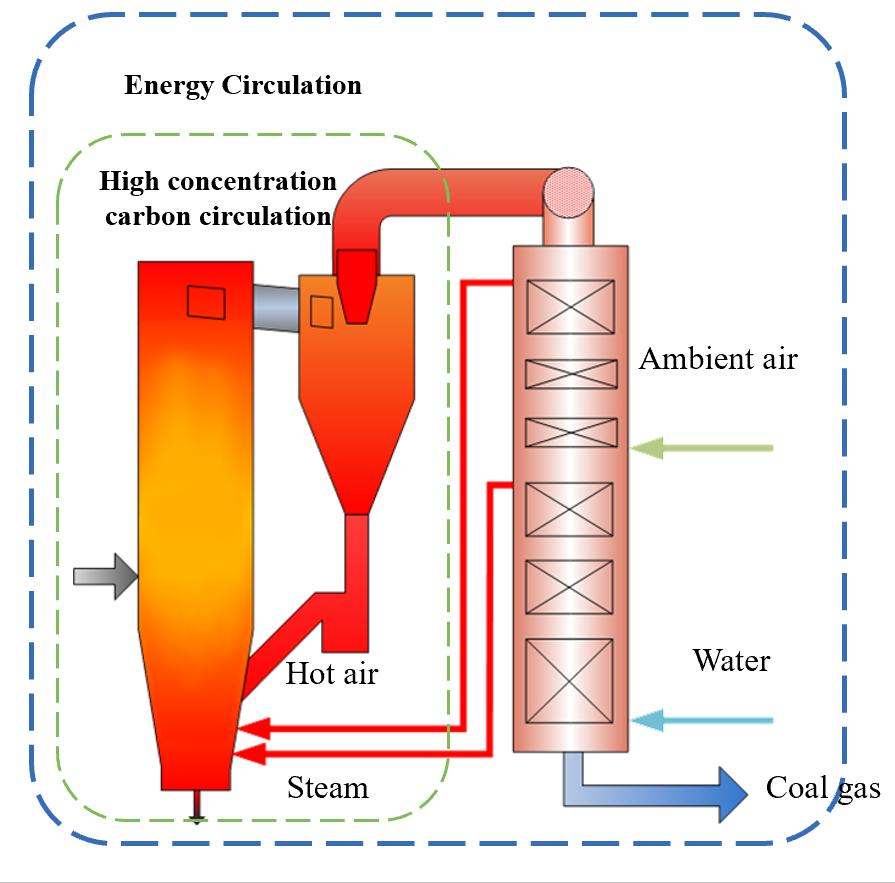

The plant uses core technologies like high-concentration material circulation and waste heat recovery from circulating fluidized bed coal gasification. This significantly reduces the production costs of clean coal gas. The dry ash removal and slag discharge technology allows the direct utilization of ash and slag, and avoids the generation of tar and phenolic substances during the production process.

Lv Qinggang explained that traditional fixed-bed gasification technology faces challenges such as tar treatment and high pollutant emissions, making it difficult to significantly reduce carbon emissions. The new gasification technology recycles carbon that would otherwise be "lost," creating a high-concentration carbon loop, controlling pollutant generation at the source, and avoiding the old approach of polluting first and purifying later. This results in significant energy savings.

Schematic diagram of circulating fluidized bed coal gasification technology

Coal is not only a fuel but also a raw material. In recent years, about 800 million tons of coal have been gasified annually in China and widely used in fields like metallurgy, chemicals, building materials, and ammonia synthesis. However, the conversion process is often associated with large carbon emissions, making coal chemicals a key area for carbon reduction.

The Institute of Engineering Thermophysics at the Chinese Academy of Sciences has long accumulated extensive research in the field of clean and efficient coal utilization. In recent years, the institute has focused on exploring carbon reduction through improved energy utilization.

The Guizhou Hongsheng Chemical Gas Head Modification Project, built using circulating fluidized bed gasification technology, has successfully been applied to ammonia synthesis. Just one gasification furnace replaced ten fixed-bed gasifiers, making the gas production process more efficient, clean, and affordable, even when using local coal with poor quality that is difficult to gasify with traditional technologies.

Guizhou Hongsheng Chemical Gas Head Modification Project

Lv Qinggang highlighted that the main feature of this technology is that it "does not pick coal." The circulating fluidized bed technology allows for high-efficiency coal gasification, significantly reducing energy consumption and carbon emissions compared to traditional fixed-bed technology.

Currently, about one-third of the raw gas in China's ammonia synthesis industry is still produced using fixed-bed gasification technology. According to a report from international consultancy McKinsey, by upgrading coal gasification equipment, China's relevant industries are expected to reduce unit coal consumption by 30% by 2030, thereby lowering carbon emissions by about 15%.

The residue left after coal gasification can also be used as fuel! The ash incineration power generation technology developed by the Institute of Engineering Thermophysics is a technology that treats and reuses gasification residues on a large scale. Its combustion efficiency is even comparable to some low-quality coals.

This technology is characterized by large fly ash processing capacity and high combustion efficiency. When combined with circulating fluidized bed gasification technology, it enables the hierarchical utilization of coal, maximizing the extraction of value from coal.

"There are many more carbon reduction technologies, and we are continually exploring how to achieve industrial applications," said Lv Qinggang. For example, further decarbonizing gasification residues can turn them into raw materials for building materials, providing alternatives for high-carbon-emitting industries and enabling high-value utilization. (Reporter: Dong Ruifeng)